Floor Standing ODM Network Cabinet for Home

Basic Info

| Type | Server Cabinet |

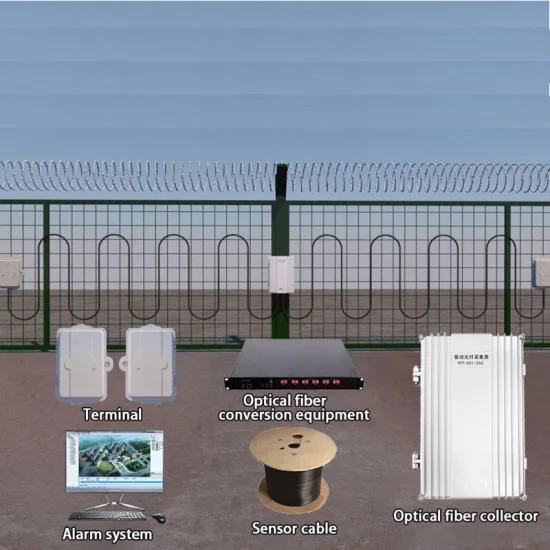

| Usage | Video Surveillance Systems, Network Integration System, Remote Monitoring System, Closed-Circuit Monitoring System, Electronic Monitoring System, Wireless Monitoring System |

| Installation | Vertical |

| Fan Number | Two |

| Capacity | 42u |

| Certification | CE, ISO, RoHS |

| Condition | New |

| Color | Black |

| Model No. | Gma61042b |

| Brand | Getwell |

| Voltage | 110V~280V |

| Cabinet Standard | 19 Inch |

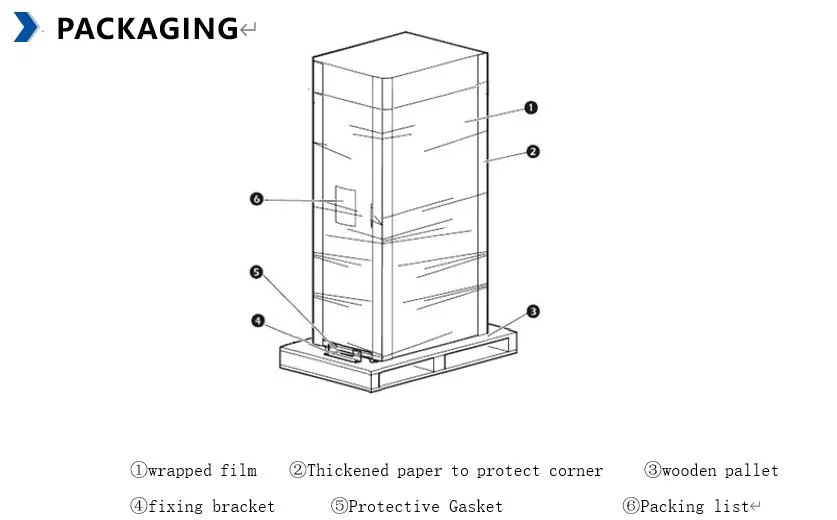

| Transport Package | Carton Box or Wooden Pallets |

| Specification | 600W*1000D*2000H |

| Origin | Guangzhou, China |

| HS Code | 850440200 |

| Production Capacity | 4000 Sets Per Month |

Product Description

Floor Standing ODM network cabinet for home

An easy-to-use, computer and network equipment storage cabinet that complies with data center, computer room and premise network equipment room requirements.

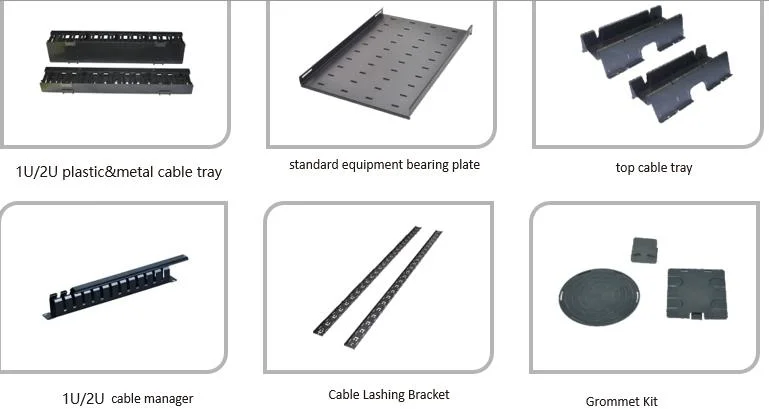

KEY FEATURES • Cabinet solution adaptable to server, network or mixed-use application • Standard configuration includes perforated front and rear doors to support front-to-rear airflow • Sized to match industry standards • Supports up to 1800 kg (3968 lb) of equipment • Thermal, power and cable management accessoriesUSE WITH • PDU Mounting Brackets • Bottom Panel • Cable Lashing Bracket • Cage Nuts Hardware Kit

RELATED PRODUCTS • Snap-In Filler Panels • Rack-Mount Shelf • Rack-Mount PDUs Detailed Photos

| Size | 600/800mm(W)×800~1200mm(D)×2000/2200mm(H) |

| Series | GMA |

| Appearance | novel and elegant, and the structure and craftsmanship are exquisite, meets the requirements of modern data center |

| Color | Black or optional |

material | Adopt high intensity high quality SPCC,Frame - 1.5mm~2.0mm 5mm clear toughened glassSide panels - 1.2mm quality SPCCTop cover - 1.2mm quality SPCCMounting angles - 2.0mm quality SPCC |

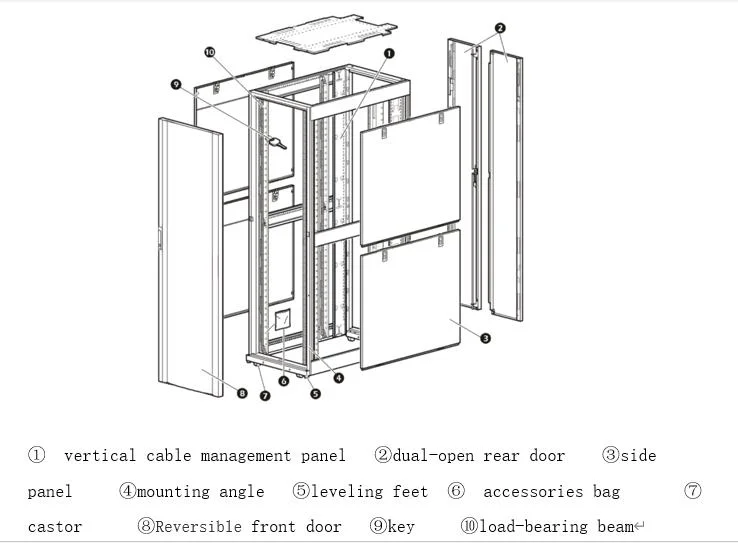

Structure | 19 inch, EIA standard, bending welded structure, removable front/rear door and side panels, up to 76% ventilation. Front door can be open from the left or right. Both doors use high-quality locks with swing handle. Single open front door and dual-open rear door, opening angle over 1100. Detachable side panels with lock(same as door), racks can be jointed by baying kit. Compatible with airflow optimization and cable management accessories. |

| wire entry | Opening top and bottom panels, reserved cable entry |

| Wire opening | The plastic cover plate is made of A1-grade flame-retardant plastic (with technical performance that meets the requirements of non-combustible and non-flammable), which ensures safe use of the product. |

Grounding | Grounding connections on doors. Roof, side panels, doors are grounded to the frame of the enclosure. Additional external grounding locations front / rear |

Mounting rail | 4 standard mounting rails in the front and rear of cabinet(quality SPPC/2.0,1U=44.45),Each rail is fixed with screws to the cabinet crossbeam, with vertical force as the main force, to make the ruler more sturdy and less prone to deformation. At the same time, the screws also fix the distance between the rails before and after adjustment. Disassembling and adjusting the distance between the rails is simple and convenient. |

| shelves | The cabinet provides a variety of equipment load-bearing plate requirements, including fixed and telescopic types, with load-bearing ranges from 60kg to 250kg to choose from. |

| Anti-seismic | The cabinet is connected to the load-bearing base through fixed installation holes at the bottom, which can resist damage caused by impact, falling, and severe shaking. It is necessary to firmly install the cabinet and the supporting load-bearing base. |

Bearing | The bottom of the cabinet is equipped with 4 horizontally adjustable leveling feet, which can be adjusted with a screwdriver for easier use. The contact surface between the leveling feet and the ground is equipped with high-strength plastic washers. The maximum static load capacity of the cabinet is up to 1800KG. |

Cable manager | On the left and right sides of the rear of the cabinet, there is a steel vertical cable bundle plate or cable trough, each with a reserved hole for quick installation of PDU. This facilitates the fixing of front and rear cables and PDUs, and greatly increases the convenience and flexibility of adjusting the cables during use. |

| hardware | Configure 40 sets M6 screws and nuts per cabinet |

surface | automatic spray-cleaning and baking-spray integrated process to produce surface coatings, first treated with phosphate rust prevention and protective mold processing, and then enter the process of electrostatic powder spraying and high-temperature baking to form a uniform, clear pattern, and super-adhesive surface coating. Ensure the product is wear-resistant and durable, which can improve the service life of the product. |

powder | This uses ICI professional high-hardness and environmentally friendly foam powder material to ensure compliance with anti-static and BS6497 international standards. The surface is phosphated and sprayed, and the surface spray thickness reaches 50-100µm, with a surface spray hardness greater than 2H and an adhesion level that meets international standards of 0. It also complies with the European ROSH standard and meets the national non-toxic and harmless spraying standard. |

| Production standard | comply with IEC297-2(19in)BSI5954,DINIn41494,41488,ANSI/EIARS-310-C,ETSI,EIA-310-D,GB/T3047-2-97. |

| Running environment | Temp :-5ºC~55ºC Humidity :≤90%(30ºC) Atmosphere Pressure :65kpa-110kpa |

Grounding request | Insulation resistance: When the temperature is 20 ± 5°C and the relative humidity is less than 90%, the insulation resistance between any non-communicating terminal and between the terminal and the frame is greater than 2 megohms. Withstanding voltage strength: Under condition 1), the AC 50Hz, 2000V effective value voltage can be sustained for one minute without breakdown between any non-communicating terminal and between the terminal and the frame. |

ACCESSORIES

| Application | Data Center or IT room of Data center, communication room, office building, weak current monitoring, shopping center, bank airport |

| Product | Professional Data Center Server Rack |

| Our Advantage | High-quality with most competitive price |

| vertically integrated processes, cost saving | |

| No cheating material | |

| Own lab keeps the quality reliable | |

| Superiority of new product research and development | |

| Easy installation,facilitate moves,adds or changes | |

| Loading Capacity | 1800 kgs |

| Depth | 800-1000-1100-1200mm |

| Width | 600mm |

| Height | 42U |

| Material | Carbon steel(Q235B) |

| Finish | Powder coating for indoor usage (the color is optional) |

| Packing way | 5 layer double corrugated paper board |

| Pallet avaliable if necessary | |

| Products Certificate | RoHS,CE |

| Manufacture System Certification | ISO 9001:2008 Quality Management System Certification |

| ISO 14001 Environmental Management System |

| Package Includes: 19″G shape 7 bending enclosure(1set),side panels(4 pcs),castors and levelling feet,M6 screws(40 sets),mesh single open front door with lock(1pc),mesh dual open rear door with lock (1pair),vertical cable management tray,Owner's Manual,certifacate,standard packageand with label. | ||||

| material | High quality SPCC | frame | G shape bending steel | |

| color | RAL9005(black) | Mounting angle | 2.0mm | |

| Front & rear door | 1.2~1.5mm | 1 U | 44.45mm | |

| Side panel | 1.2mm | Net weight | 120KG | |

| standard | Meet EIA-310-D 19″standard production request | |||

Company Profile

Established in 2008, Guangzhou Getwell Electronics has been delivering high quality, innovative products and technologies to the IT industry for over 15 years. We focus on data center infrastructure design, construction, manufacturing, operation and maintenance. From 2008 we started to research and develop Micro Modular data center product and build own factory. Getwell pays great attention to R&D and its engineer teams include industrial designer, structure engineers, software engineers, power distribution engineers and HAVC engineers.

Getwell is aimed at continuous improvement product, quality and enlargement of functionality of the products. We keep moving forward learning the world experience in the IT field and needs of our customers, trying to improve and bring our solutions to the level of world IT leaders and even surpassing in some areas. We associates with modern, innovative, convenient, sturdy, secured and high quality product. We follow the tendency of "new generation" of mounting constructions: manufacturing of designs; stable performance and high loading capacity of the structure; low cost on storage and transport thanks to the compact packing and assembling construction. Aim on giving our customers confidence that solutions Getwell guarantees.

FACTORY TOURFAQ

1. Why choose us?

a. we are 15 years factory in producing data center infrastructure products.

b. we have 10+ people in quality management.

c. we have 20+ Process and R&D technicians.

d. we have 10000+ suquare meter factory area.

2. It takes how many days for products preparation?

Usually 25-30 days.

3. What's the trading term for selecting?

FOB, EXW, CIF, CFR, DDP, DDU.

4. I want to buy but I don't have any experience about international trading, what can I do?

Contact the sales for delivery door to door.

5. Which certification we have got?

For manufacturer: ISO 9001: 2008, OHSAS 18001, ISO 14001:2004 For products: CE, ROHS,CQC,etc.